Laser welding machines offer state-of-the-art technology for precise, repeatable welded joints in various industries. The machines use a focused laser beam to quickly and accurately weld metals and non-iron metals such as bronze alloys, copper, steels and stainless steels, aluminum and even plastics.

They enable burn-free welding seams with minimal thermal intervention and reduce process failures due to welding seam fractures to virtually zero. The integrated CNC control enables 100% repeatable welding results combined with the shortest downtimes in your process chain, maximum efficiency and the lowest operating costs. This makes them ideal for companies that want to increase their production efficiency while delivering high-quality, fault-free products.

Thanks to the well thought-out design and optimized solutions, the operator can use the laser welding machine without any problems after a short training session. The intuitive user guidance makes it easy and efficient to get started.

The machine generates only low indirect radiation. The operator only needs safety goggles to protect himself from the intense light of the laser.

Laser welding is up to 10 times faster than conventional methods, which significantly increases productivity. This leads to faster processing times and greater efficiency in production.

The concentrated laser beam keeps the heat-affected area small, which causes only minimal structural changes to the material. This ensures precise welding seams without material damage.

Laser welding machines offer 100% reproducibility of the weld seams. The joints are not only aesthetically pleasing, but also extremely strong and sturdy.

The machine can weld very thin materials, such as 0.20 mm stainless steel. This opens up new possibilities in fine machining and precision manufacturing.

In addition to welding, the machine can also be used for laser cleaning. This extends the range of applications and ensures clean, ready-to-machine surfaces.

The machine offers a cutting option that enables precise cuts without mechanical reworking. This saves time and improves production efficiency.

The laser enables unique shaping without any consumables, which ensures a better seal around the workpiece. This significantly improves the sealing performance.

The customized clamping fixture design enables adaptation to different product specifications. Retooling is quick and takes less than 5 minutes.

Thanks to precise digital control, almost all desired cutting profiles can be executed. This enables complex geometries and high repeat accuracy for every application.

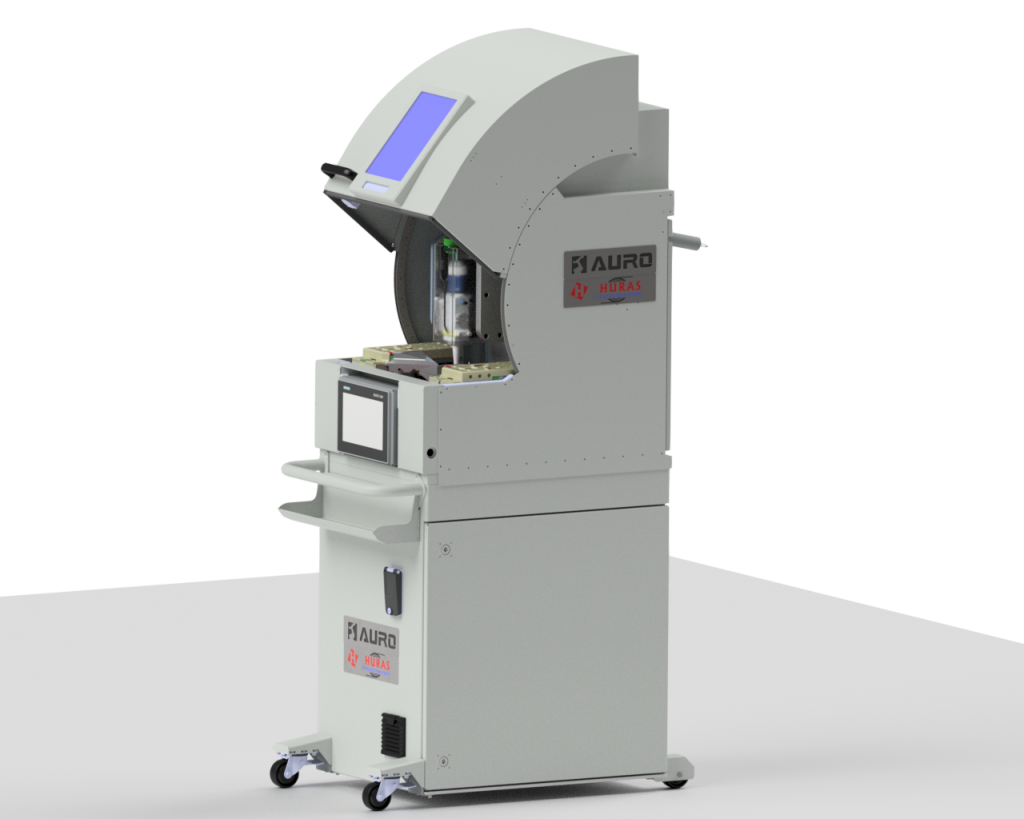

The laser welding machine impresses with its space-saving design and requires only a small footprint. This allows the machine to be easily integrated even in cramped production environments without taking up valuable space.

Would you like advice, a personal offer or further information about our product? Then please contact us directly using our form.

A laser welding machine uses the energy of a highly focused laser beam to join materials. The process is based on the intense heat generated by the laser to melt the surfaces of the workpieces and weld them together. The process is extremely precise and efficient and is suitable for various materials and applications. The following process is typical:

You can weld various materials with a laser welding machine: